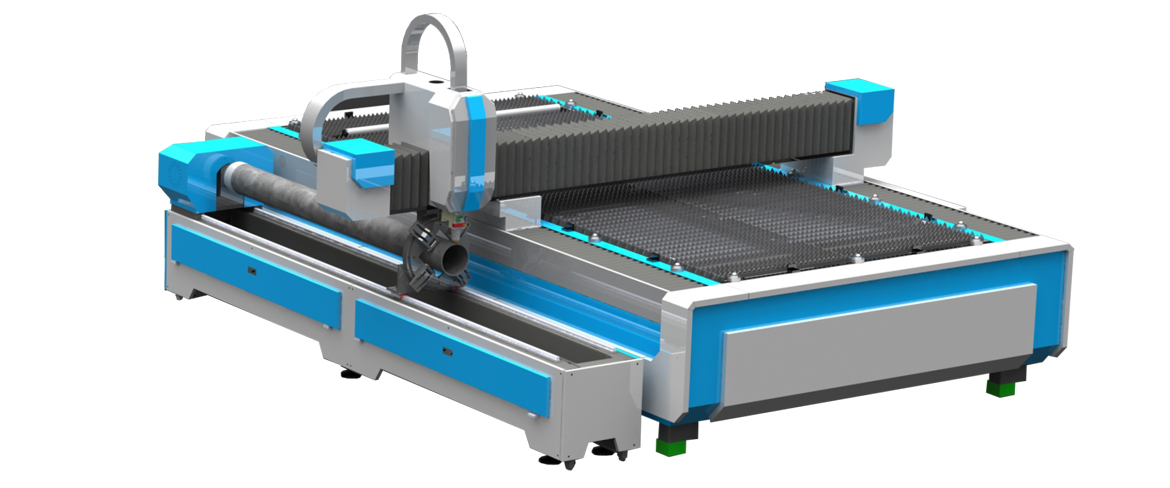

Gloria 480F - Fiber Laser Metal Cutting Machine

Overview

FIBER LASER TECHNOLOGYBriefly, fiber laser light is created by banks of diodes. The light is channeled and amplified through fiber optic cable similar to that used for data transfer. The amplified light, on existing the fiber cable, is collimated or straightened and then focused by a lens onto the material to be cut.

FIBER LASER CUTTING WORKING PRINCIPLEFiber laser cutting machine is equipped with the most advanced international imported fiber laser source which generates powerful laser focused on objects to cause instant melting and evaporation. Automatic cutting is controlled by digitalized mechanic system. This hi-tech machine has condensed the advance technologies of fiber laser, digital, and precise mechanics.

FIBER LASER CUTTING MACHINE APPLICATION FIELDSApplicable to fast cutting on plate or tube in metal, mainly for cutting on SS, Carbon steel, Manganese steel, galvanized plate, alloy plate, rare metal; Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, hardware and metal processing.

FIBER LASER CUTTING ADVANTAGESFiber lasers are up to ten times more energy efficient than traditional YAG and Co2 laser systems. And, consuming little to no energy when not active, the annual energy savings can attract government grant funding for industrial energy efficiency programs.

Fiber laser have no mirrors to adjust or align, and no lamps to replace. Maintenance is minimal, so utilization and up-times are maximized. The laser really are designed as shop floor industrial tools.

Fiber laser machine is of low cost which consume very low electricity every hour. It has a lifespan of 1,00,000 hours. Fiber laser is maintenance free and its higher cutting speed and efficiency, speed of cutting plate can reach over 10 meters per minute.

Feature & Technical Advance

FSCUT CLOSED–LOOP CONTROL SYSTEM

Powerful Hardware Configuration

The hardware of closed- loop control system consists of BMC1214 four axis motion card and BCL3724 terminal board. The system adopts high- precision 16- bit DA chip with low- noise and low-drift coefficient signal; Powerful real- time computing power is provided by High-performance ARM processor and FPGA coprocessor; The system can run more fast and smooth owning to 32 large capacity SDRAM memory; Reliable communication can be still achieved in harsh industrial environment due to high- speed differential communication bus. The system is safe, reliable and easy to manage due to coming with its time encryption and decryption function without needing other dongle.

CYPCUT SOFTWARENew function of CypCut cutting software

Better speed, better convenience, better security and better use:

Start processing immediately without waiting

It can operate with smooth, high-speed and precision due to leading high-speed NURBS real-time interpolation, and start processing in any position without waiting. Whenever stop, alarm or power-down happens, it can continue to work from the breakpoint.

One Graph, Numerous Processes

You can complete a variety of processes by drawing only one graph. Pre-piercing: Piercing in advance according to your graph. Cutting with a film: Cutting after eliminating the film by stripping process. Secondary cooling: Processing once following immediate cooling along track.

Fast & Practical Scanning Cutting

Now it is possible to scan and cut straight line in any direction, and to naturally and progressively cut circular arc of arbitrary arrangement. We can ensure the tangent between circular arc and scan with smooth and high-speed.

Convenient Seeking- Edge & Locating

Not only capacitive seeking- edge, but also infrared and visual orientation can be easily operated using BCS100. The position and angle can be simultaneously determined in any case mentioned above.

BCS100 HEIGHT CONTROLLER

| V3.0 | |

| Max Moving Speed | 999 mm/s |

| Max Acceleration | 2G |

| Vibration Elimination | Following the front point & edge with easy vibration |

| Capacitance Mutation Restraint | 10% |

| Min Adaptable Inflexibility Requirement | 2 hz |

| Firmware Upgrade | U Disk / Ethernet |

| DA Resolution | 16 Bit |

| DA zero drift | 3 Mv |

| DA Response Time | 0.01 Mv |

| DA Linearity | 0.1% |

| Positioning Accuracy | 0.001 mm |

| Alarm Information & power Down Save | Yes |

Applications of Fiber Laser Cutting Machine Gloria Series

|

|

|

|

|

|

The Power, Cutting Thickness & Speed Parameters

| Material | 300W | 500W | 750W | 1000W | 1500W | 2200W | 3300W | 4400W |

| MS | 2.5 | 5 | 6-8 mm | 8-10 mm | 12-14 mm | 16-18 mm | 20-22 mm | 22-24 mm |

| SS | 1.5 | 3 | 4 mm | 5 mm | 6 mm | 8 mm | 10 mm | 12 mm |

| ALUMINIUM | -- | -- | 1.6 mm | 2.5 mm | 5 mm | 6 mm | 8 mm | 10 mm |

| BRASS | -- | -- | 1.6 mm | 2 mm | 3 mm | 3 mm | 6-8 mm | 8 mm |

| COPPER | -- | -- | 1 mm | 2 mm | 2 mm | 3 mm | 6-8 mm | 8 mm |

| POWER CONSUMPTION | 7 | 9 | 12 kw | 15 kw | 18 kw | 22 kw | 28 kw | 34 kw |

| WATT | 220V | 220V | 220V | 440V | 440V | 440V | 440V | 440V |

Technical Specifications of Laser Engraving Machine Gloria Series

| Model | GLORIA-480F | GLORIA-510F |

| Working Area | 4 x 8 Feet | 5 x 10 Feet |

| Laser Type | Imported Original Fiber Laser | |

| Laser Wavelength | 1070 nm | |

| Laser Output Power | 300w / 500W / 750W / 1000W / 1200W | |

| Cutting Tickness | 0.2-5 mm | |

| Max. Cutting Speed | 30000 mm/min (Adjustable according to defferent cutting thickness) | |

| Position Accuracy | ≤ ± 0.04 mm | |

| Minimum Line Width | ≤ 0.12 mm | |

| Cooling System | Water Cooling | |

| Driving System | MITSUBISHI / YASKAWA Servo motor and Drivers | |

| Transmission | X axis with imported ball screw, Y axis is imported square rail | |

| Working Voltage | 380V / 220V | |

| Total Power Consumed | 9 KW | |

| Above Specifications are subject to change without prior notice. | ||